Workshop projects

2024 was an organizing, tidying and getting-rid-of-things year. My contribution was tidying the workshop, starting with the piles of wood, some of which were still tied in bundles and labelled “Workshop” from the 2003 move to this house. I put up the storage racks I’ve had for three? four? well, maybe five years to get most of the long pieces up off the floor and built an organizer for the small pieces, which conveniently got rid of many of the smaller pieces.

With the wood piles sorted, I moved the table saw and outfeed table from the centre of the workshop and gained some open space, but lost the ability to push 8′ bits of wood through the saw. If I want to do that, I can move the saw. We shall see.

Underutilized tools

The radial arm saw which I had before we got married (so 51-52 years ago) hasn’t been assembled since we got here. The plan is to build a workstation housing the mitre saw and the radial arm, side by side. That should use up my plywood supply!

As well as tidying and organizing, I got rid of some bulky tools that I wasn’t using, and the bandsaw, which I used occasionally but needed new rubber “tyres” on the three wheels (to cushion the blade and keep it tracking well) which would have been $90 and a lot of fuss. In the end I decided I didn’t want to invest in an inferior tool and besides, I had no place to put it. So out it went.

Finishing up

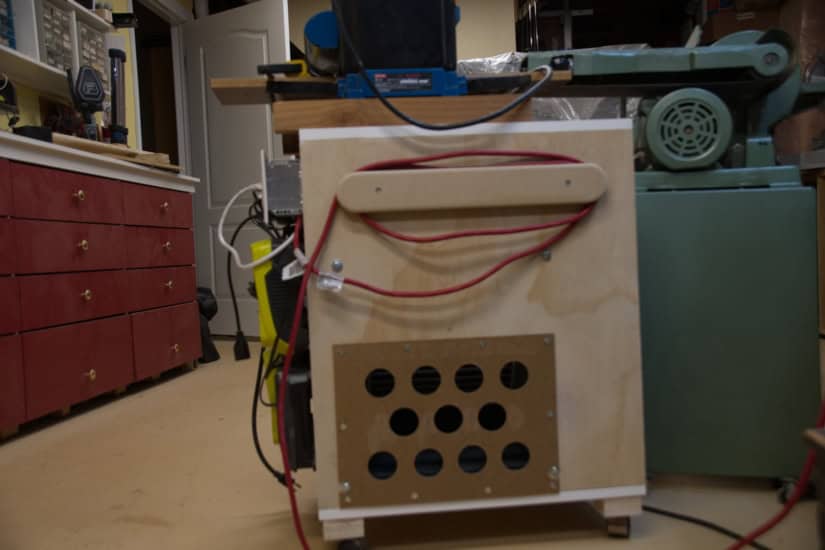

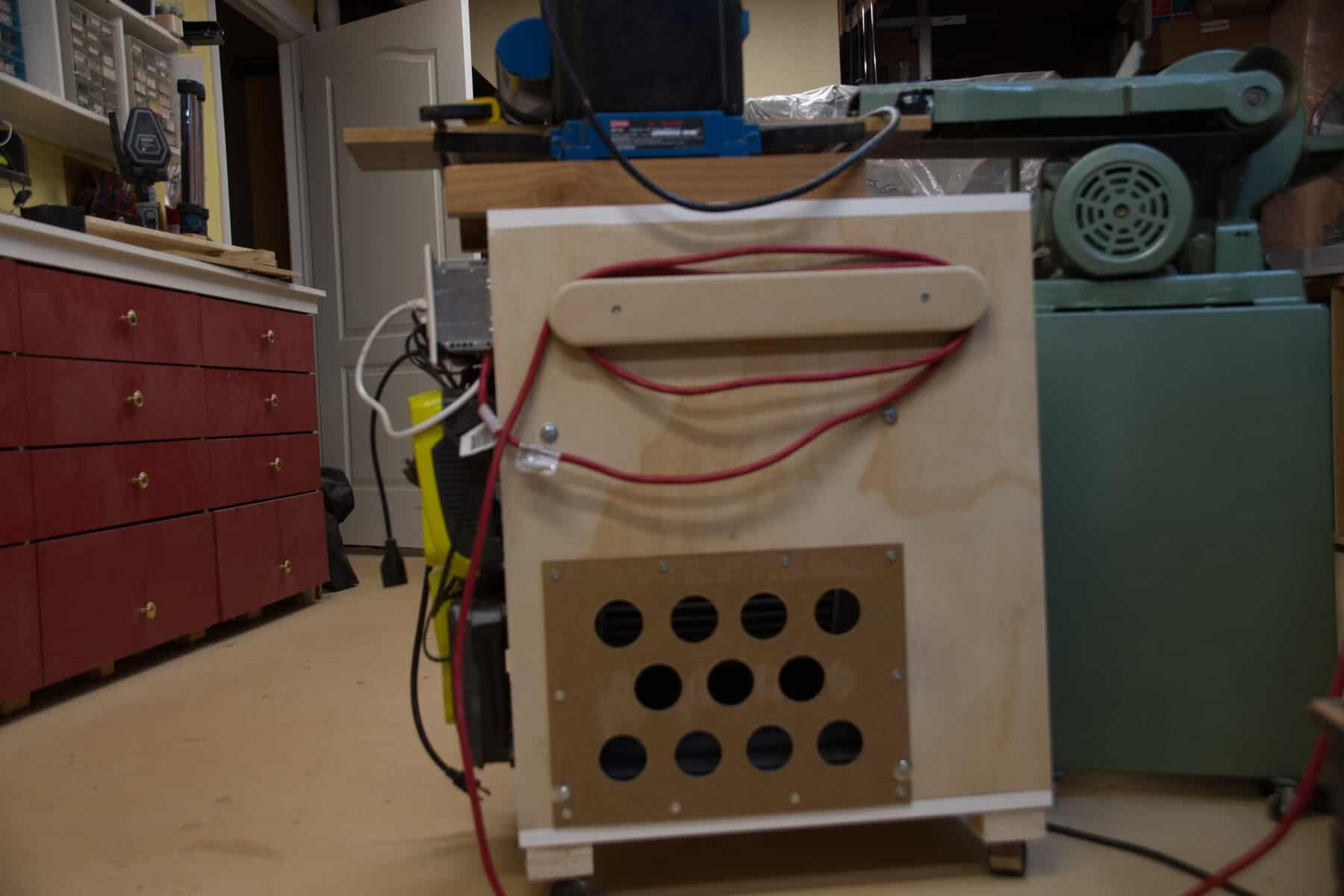

In the middle of all that, I put a cover on the fan outlet (the thing with 11 large circles in it) so that cats and small children can no longer closely investigate the spinning wheel of death. Oh, and I added a place to wind the power supply cord on, both there and on the router table. Not bad, getting that done in less than 10 years. I think.

Getting a handle on things

I was really pleased to fix the handle that locks the table saw fence. After only 45 or so years of probably overtightening the handle the steel threads on the end of the cross rod stripped out the threads in the soft aluminium handle (unfortunately when I was cutting some wood, and wondering why the blade was jamming – it was the fence moving.) My first solution was to replace the handle with a plastic knob which had a thread that matched the rod.

That worked well, until I found that if I didn’t line up the knob with the two wings straight up and down, one wing stuck out and interfered with the wood I was cutting. I had planned to use a threaded insert in a home-made replacement handle, but then I realized I could drill out the old aluminium handle, add four small holes for the prongs on the insert and press-fit the insert into the handle. All the stress was rotational, so it’s not likely to pull out. Now I know why they designed the handle to be long and thin – it can’t get in the way of any wood being cut because it’s narrower than the fence.

Capping it off

Just to show I did need a workshop, I designed and made replacement solid wood fence post caps to replace the two piece caps I had made 19 years ago. Apparently even cedar rots away when it gets wet enough and the water was getting between the two parts of the old caps – they were in bad shape. I milled up one of the old deck railings which was thick enough to get a nice profile similar to (but better looking than) the old ones. Plus the step is sloped so water runs off!

More Chucking and giving

While we were in the purging mood, we cleaned out the spare bedroom, getting rid of outdoor coats, dozens of Disney VHS tapes, and electronics that had gone upstairs to die. I also sorted through stereo equipment I had stored “temporarily” in the basement and found homes for most of it, including (surprisingly) a six-disk CD player. Who would have guessed someone would be thrilled to find one of those!

In the kitchen, Mary-Jo was ruthless in purging old gadgets and appliances, and a wheel barrow load of Tupperware, some of it with matching lids.

We also found homes for our corn plant from the kitchen that Mary-Jo’s mother gave us, a Stephanotis that used to belong to said mother, a Pothos that was given to us as a shower present, and another eight or so smaller (and younger) plants.

There was also my beloved shoe and other nice cardboard boxes collection and some clothing purges. Not enough gone yet, but a good start and enough experience to expunge the idea that “we could make a lot of money selling this stuff” – it’s mostly not worth the time it takes.

Outside tasks

Last year’s paving stone overhaul got pretty much completed this year, with most of the front areas just getting the weeds removed and polymeric sand added, but one area where two pavers were lifting a bit turned into a major reno when I found extensive tunnelling that needed to be filled. I’m still not sure if they were actual tunnels or places where the old ash tree roots had rotted away.

I went back to the basketball post project, removing more concrete from the base, but my plan to cut the post with an angle grinder was ill-founded (the blade won’t reach to the middle when used at an angle) and plan B to use a diamond blade in a Sawzall fizzled when the steel post turned out to be too tough for it. Plan C is to go back to the angle grinder, but cut the post horizontally an inch or so above the concrete rather than trying to cut at the surface of the concrete. Stay tuned!

Technology

If you’re reading this on a web site that looks different from the last time, it means I’ve managed to finish my WordPress theme re-write. I may chronicle my adventures in a later post, but right now let’s just say that technology isn’t always as much fun as I’d like it to be. The trouble is, I’m still excited to solve the problems, and I enjoy conquering new learning curves and seeing results. I expect you’ll hear new grumbles next year as well!

One response to “DIY Projects ’24”

R2D2 nanoo nanoo….love you